Experience Superior Protection With Ceramic Coatings: a Thorough Introduction

Ceramic coverings have become an advanced remedy for those looking for improved security for industrial and vehicle surfaces. Consisted of mostly of silicon dioxide, these coatings create a durable, hydrophobic barrier that not just shields versus ecological dangers such as UV rays and chemical exposure however also considerably minimizes the frequency of maintenance. As we explore the complex benefits, application methods, and just how they stack up versus conventional alternatives, it comes to be evident that the financial investment in ceramic finishings might redefine your approach to surface area protection. What elements of this technology might shock you?

What Are Ceramic Coatings?

Ceramic layers are innovative safety layers applied to surface areas, mainly in commercial and automobile applications, to improve resilience and resistance to ecological factors. Composed of silicon dioxide (SiO2) originated from natural products, these layers develop a solid, hydrophobic layer that bonds chemically with the substrate, creating a resilient shield versus various assailants such as UV rays, chemicals, and physical abrasions.

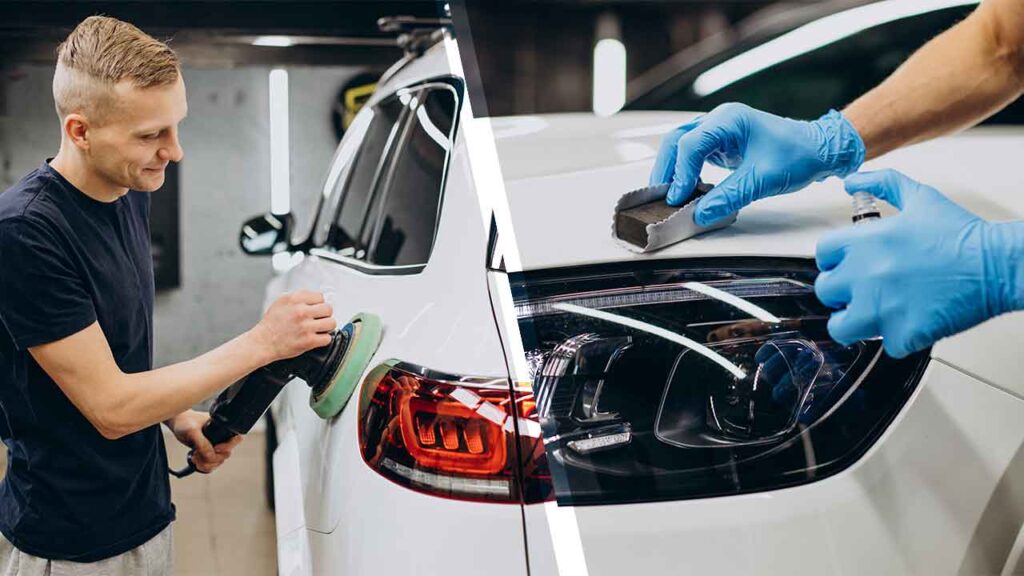

The application process generally entails complete cleansing and prep work of the surface area, adhered to by the specific application of the ceramic layer. Once cured, the finishing solidifies right into a resilient layer that can dramatically extend the life-span of the surface it safeguards. Unlike conventional waxes or sealers, ceramic finishings provide a resilient service that calls for very little maintenance.

These layers are not limited to vehicle coatings; they are also used in aquatic, aerospace, and commercial setups, where they give substantial benefits in regards to efficiency and durability. Their flexibility and efficiency in protecting surfaces against wear and tear make ceramic coatings an increasingly popular option for both specialists and enthusiasts seeking to maintain the honesty and appearance of useful possessions.

Advantages of Ceramic Coatings

Additionally, ceramic layers exhibit outstanding hydrophobic residential or commercial properties, enabling water and various other liquids to grain up and roll off surfaces - Orlando Car Care Ceramic Coatings. This self-cleaning effect dramatically reduces the time and initiative needed for upkeep, as dirt and crud are much less most likely to stick. Additionally, ceramic finishings are resistant to engraving and damaging, which better preserves the stability of the underlying surface

One more crucial advantage is the thermal resistance used by ceramic finishes, which can endure high temperature levels without deteriorating. This top quality is especially beneficial for vehicle applications, where engine elements and exhaust systems undergo extreme warm.

Application Process Clarified

Accomplishing ideal results with ceramic layers calls for a careful application procedure that guarantees correct attachment and performance. For auto applications, repaint correction may be needed to address blemishes, making certain the surface area is as perfect as feasible.

Once the surface area is prepared, it is important to apply the ceramic finishing in a regulated atmosphere, ideally in a garage or shaded location to prevent direct sunshine and dirt. Utilizing a foam applicator or a microfiber fabric, the layer should be used uniformly in little areas, permitting optimum control during application. A curing time of roughly one to two hours is suggested before exposing the surface to moisture.

After the initial healing, numerous layers might be applied to improve toughness and gloss, with each layer calling for ample healing time. It is critical to inspect the surface for any kind of high areas or irregular application and to buff these areas as needed, ensuring a flawless surface that makes best use of the safety advantages of the covering.

Upkeep Tips for Longevity

Appropriate upkeep is necessary to taking full advantage of the long life of ceramic finishes, guaranteeing that the safety layer continues to perform properly over time. Regular cleaning is important; make use of a pH-balanced, mild soap and a microfiber clean mitt to avoid scraping the surface. It is a good idea to clean the automobile every 2 weeks or even more frequently if revealed to harsh elements.

After washing, thoroughly dry the surface with a clean microfiber towel to avoid water spots. Additionally, applying a ceramic maintenance spray every couple of months can replenish the covering's hydrophobic homes, enhancing security versus contaminants.

Prevent utilizing abrasive cleansing devices, waxes, or sealants that may deteriorate the ceramic layer. Instead, choose for non-abrasive products particularly created for ceramic layers.

Evaluate the covering occasionally for any type of signs of wear or damage, check out here and address these issues quickly to keep ideal efficiency.

Contrasting Ceramic Coatings to Alternatives

When examining protective options for vehicle surfaces,Preserving ceramic finishes is simply one element to consider. When contrasting ceramic finishings to options such as wax, sealants, and paint protection films, several crucial aspects arise.

Paint protection movies (PPF) are one more popular choice, supplying outstanding physical security versus chips and scrapes. They can be much more pricey and may require professional setup, unlike ceramic finishings, which can frequently be used by an experienced DIY enthusiast. Furthermore, ceramic coverings enhance the vehicle's gloss and depth, supplying visual benefits that alternatives may not match.

Final Thought

In conclusion, ceramic finishes stand for a substantial innovation in surface area security for vehicle and commercial applications. With very little upkeep requirements and resilient performance, ceramic coverings not only secure the integrity of surfaces yet also enhance their aesthetic allure.